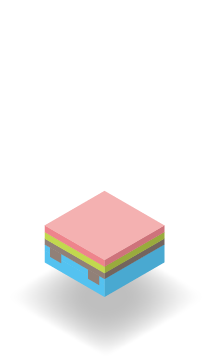

Patterning

Replacement demand for our materials such as quartz, ceramics, silicon parts,

and silicon carbide is growing in proportion to the increase in production by semiconductor customers.

We offer a variety of semiconductor-related products, including a thermoelectric cooler module, which has recently been adopted as a cooling plate of manufacturing equipment for controlling the wafer temperature.

![]() 1. Silicon Ingot Cutting

1. Silicon Ingot Cutting

[Products used in this process]

●Silicon Wafers

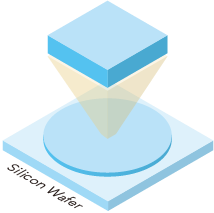

![]() 2. Silicon Wafer

2. Silicon Wafer

[Products used in this process]

●Silicon Wafers

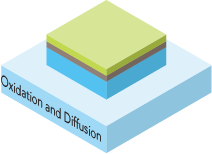

![]() 3. Oxidation and Diffusion

3. Oxidation and Diffusion

[Products used in this process]

●Vacuum Seals

●Quartz Products

●Ceramics

●SiC Parts (CVD-SiC)

●Silicon carbide parts

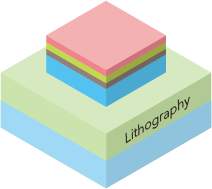

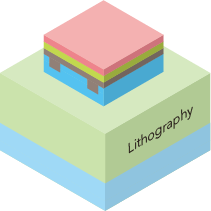

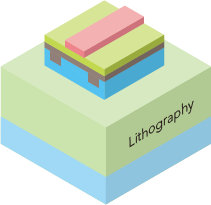

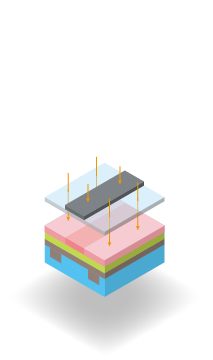

![]() 4. Lithography

4. Lithography

[Products used in this process]

●Vacuum Seals

●Ceramics

●SiC Parts (CVD-SiC)

●Silicon Wafers

●Process Parts Cleaning

●Thermo-electric Modules

●CMS

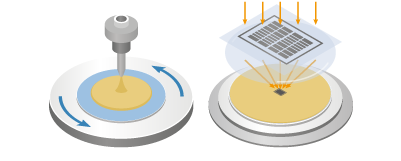

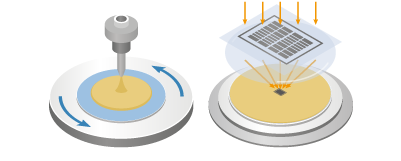

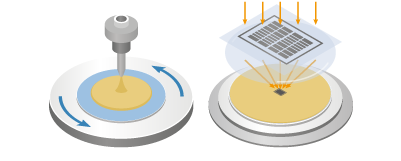

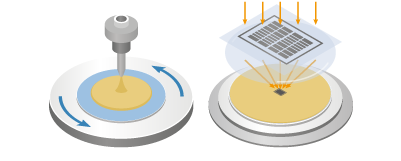

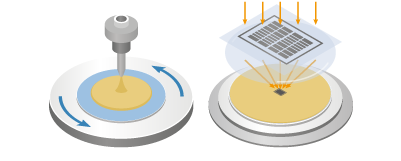

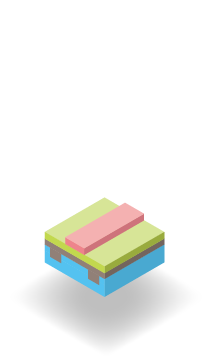

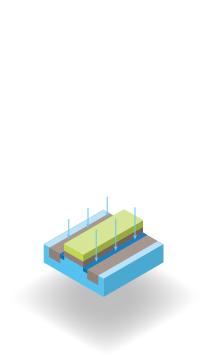

![]() 5. Lithography

5. Lithography

[Products used in this process]

●Vacuum Seals

●Ceramics

●SiC Parts (CVD-SiC)

●Silicon Wafers

●Process Parts Cleaning

●Thermo-electric Modules

●CMS

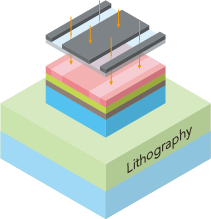

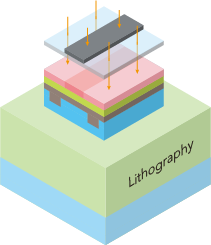

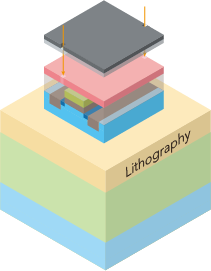

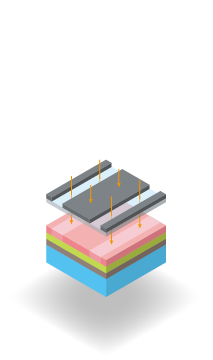

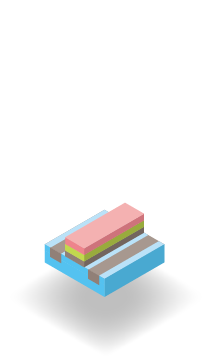

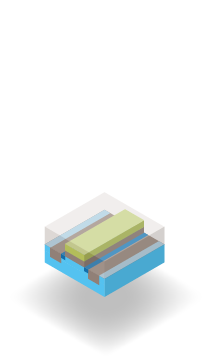

![]() 6. Lithography

6. Lithography

[Products used in this process]

●Vacuum Seals

●Ceramics

●SiC Parts (CVD-SiC)

●Silicon Wafers

●Process Parts Cleaning

●Thermo-electric Modules

●CMS

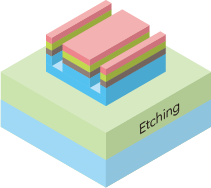

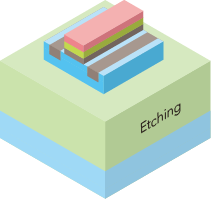

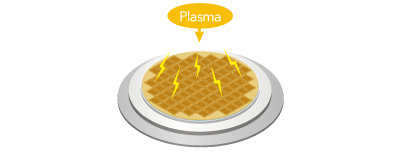

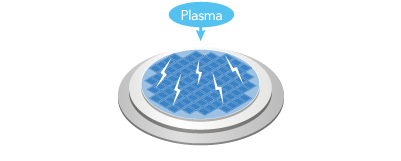

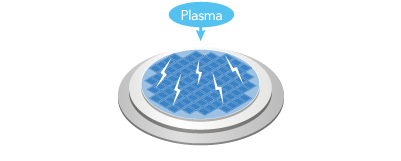

![]() 7. Etching

7. Etching

[Products used in this process]

●Vacuum Seals

●Quartz

●Ceramics

●SiC Parts (CVD-SiC)

●Silicon carbide parts

●Silicon parts

●Process Parts Cleaning

●CMS

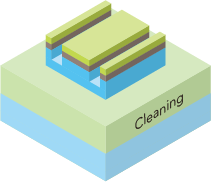

![]() 8. Cleaning

8. Cleaning

[Products used in this process]

●Vacuum Seals

●Quartz

●Ceramics

●SiC Parts (CVD-SiC)

●Silicon carbide parts

●Silicon parts

●Process Parts Cleaning

●CMS

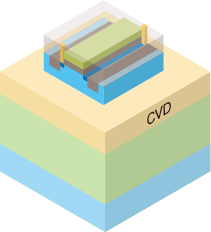

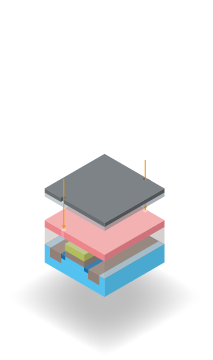

![]() 9. CVD

9. CVD

[Products used in this process]

●Vacuum Seals

●Quartz

●Ceramics

●SiC Parts (CVD-SiC)

●Silicon carbide parts

●Silicon parts

●Process Parts Cleaning

●CMS

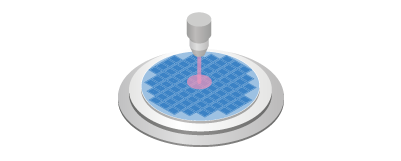

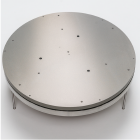

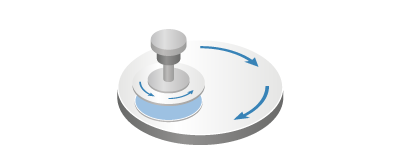

![]() 10. CMP

10. CMP

[Products used in this process]

●Vacuum Seals

●Quartz

●Ceramics

●Silicon parts

●Process Parts Cleaning

●CMS

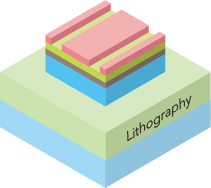

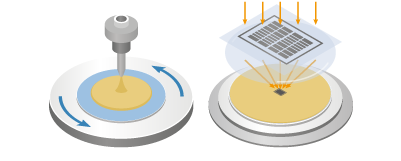

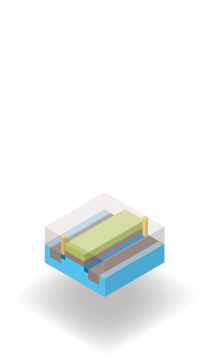

![]() 11. Lithography

11. Lithography

[Products used in this process]

●Vacuum Seals

●Ceramics

●SiC Parts (CVD-SiC)

●Silicon parts

●Process Parts Cleaning

●Thermo-electric Modules

●CMS

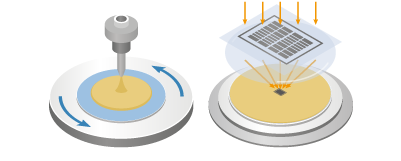

![]() 12. Lithography

12. Lithography

[Products used in this process]

●Vacuum Seals

●Ceramics

●SiC Parts (CVD-SiC)

●Silicon parts

●Process Parts Cleaning

●Thermo-electric Modules

●CMS

![]() 13. Lithography

13. Lithography

[Products used in this process]

●Vacuum Seals

●Ceramics

●SiC Parts (CVD-SiC)

●Silicon parts

●Process Parts Cleaning

●Thermo-electric Modules

●CMS

![]() 14. Etching

14. Etching

[Products used in this process]

●Vacuum Seals

●Quartz

●Ceramics

●SiC Parts (CVD-SiC)

●Silicon carbide parts

●Silicon parts

●Process Parts Cleaning

●CMS

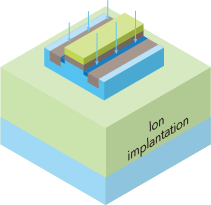

![]() 15. Ion implantation

15. Ion implantation

[Products used in this process]

●Quartz

●Silicon parts

●Process Parts Cleaning

●CMS

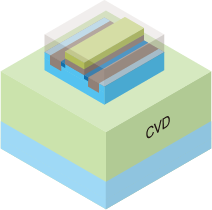

![]() 16. CVD

16. CVD

[Products used in this process]

●Vacuum Seals

●Quartz

●Ceramics

●SiC Parts (CVD-SiC)

●Silicon carbide parts

●Silicon parts

●Process Parts Cleaning

●CMS

![]() 17. Lithography

17. Lithography

[Products used in this process]

●Vacuum Seals

●Ceramics

●SiC Parts (CVD-SiC)

●Silicon parts

●Process Parts Cleaning

●Thermo-electric Modules

●CMS

![]() 18. CVD

18. CVD

[Products used in this process]

●Vacuum Seals

●Quartz

●Ceramics

●SiC Parts (CVD-SiC)

●Silicon carbide parts

●Silicon parts

●Process Parts Cleaning

●CMS

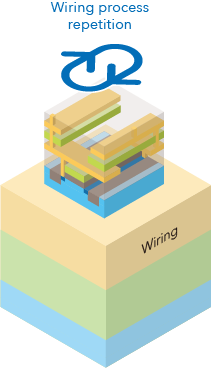

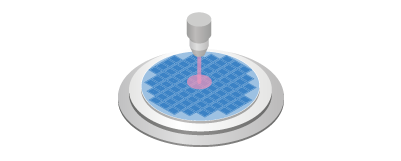

![]() 19. Wiring

19. Wiring

[Products used in this process]

●Vacuum Seals

●Quartz

●Ceramics

●SiC Parts (CVD-SiC)

●Silicon parts

●Process Parts Cleaning

●CMS

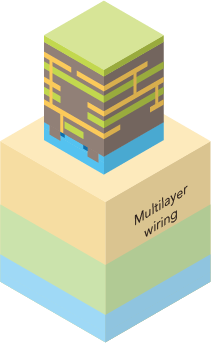

![]() 20. Wiring

20. Wiring

[Products used in this process]

●Vacuum Seals

●Quartz

●Ceramics

●SiC Parts (CVD-SiC)

●Silicon parts

●Process Parts Cleaning

●CMS

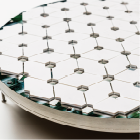

![]() 21. Assembly

21. Assembly

Cut the wafer into chips

Seal with ceramic resin

[Products used in this process]

![]() 22. Inspection

22. Inspection

Check functionality,

environmental characteristics,

reliability, etc

[Products used in this process]

●Ceramics

![]() 23. Completion

23. Completion

Print serial number

and it’s ready

[Products used in this process]

●Quartz

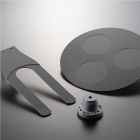

Outer

tube

Wafer boat

Cleaning chamber

●Silicon carbide parts

Wafer boat

Inner

tube

Injector

●SiC Parts (CVD-SiC)

Wafer

boat

Wafer boat

assembly

Silicon carbide

dummy wafer

●Ceramics

Wafer tray

& hand

Wafer

clamp

Probe card

●Thermo-electric Modules

Cooling

plate

Cooling

plate

(internal structure)

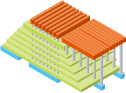

▶︎End products

Manufacturing equipment examples

-

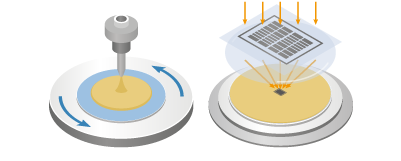

Lithography

Lithography -

Coater/developer

(resist coating)

Exposure equipment

(exposure and development using photomask)

-

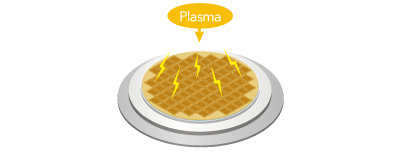

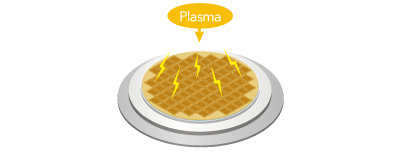

Etching

Etching -

Dry etching equipment

(plasma etching)

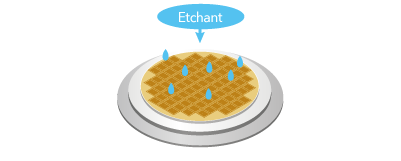

-

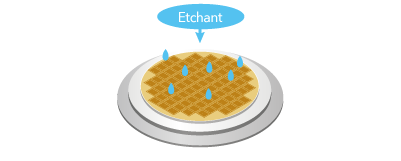

Cleaning

Cleaning -

Wet etching equipment

(liquid etching)

-

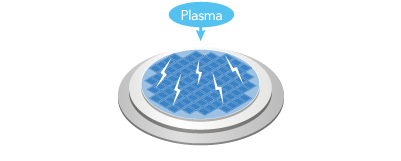

CVD

CVD -

CVD equipment

(insulating film forming)

-

CMP

CMP - (polishing / planarization)

-

Ion implantation

Ion implantation - (Formation of Element)

-

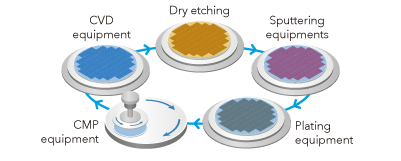

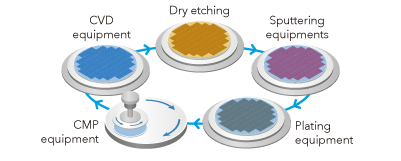

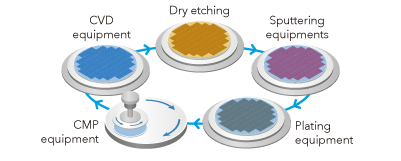

Wiring

Wiring -

CVD equipment + Dry etching equipment

+ Sputtering equipment+ Plating equipment

+ CMP equipment

| Semiconductor manufacturing process▶︎ |

Silicon base | Assembly ・Inspection |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Lithography | Etching | Process Tools Parts Cleaning | CVD | CMP | Ion implantation | Wiring | |||||

| Transistor layer 〜 Wiring / Multilayer wiring | |||||||||||

| ▼ Products of Ferrotec used in each process | |||||||||||

| Vacuum Seals |

|

|

|

|

|

|

|

|

|

||

| Quartz |

|

|

|

|

|

|

|

|

|

||

| Ceramics |

|

|

|

|

|

|

|

|

|

||

| SiC Parts (CVD-SiC) |

|

|

|

|

|

|

|

|

|

||

| Silicon carbide parts |

|

|

|

|

|

|

|

|

|

||

| Silicon parts |

|

|

|

|

|

|

|

|

|

||

| Process Tool Parts Cleaning |

|

|

|

|

|

|

|

|

|

||

| Thermo-electric Modules |

|

|

|

|

|

|

|

|

|

||

| CMS |

|

|

|

|

|

|

|

|

|

||